ngram

listlengths 0

9.89k

|

|---|

[

"possible values, or does it have a few patterns where",

"algorithm to calculate a pattern for any of those possible",

"Cura have an algorithm to calculate a pattern for any",

"Looking in the Cura interface, I can set any whole",

"number 0-100 for the infill percentage. Does Cura have an",

"in the Cura interface, I can set any whole number",

"calculate a pattern for any of those possible values, or",

"percentage. Does Cura have an algorithm to calculate a pattern",

"for any of those possible values, or does it have",

"values, or does it have a few patterns where it",

"have an algorithm to calculate a pattern for any of",

"I can set any whole number 0-100 for the infill",

"to calculate a pattern for any of those possible values,",

"have a few patterns where it selects the closest one?",

"a pattern for any of those possible values, or does",

"the infill percentage. Does Cura have an algorithm to calculate",

"or does it have a few patterns where it selects",

"an algorithm to calculate a pattern for any of those",

"any whole number 0-100 for the infill percentage. Does Cura",

"does it have a few patterns where it selects the",

"Cura interface, I can set any whole number 0-100 for",

"set any whole number 0-100 for the infill percentage. Does",

"any of those possible values, or does it have a",

"0-100 for the infill percentage. Does Cura have an algorithm",

"the Cura interface, I can set any whole number 0-100",

"whole number 0-100 for the infill percentage. Does Cura have",

"it have a few patterns where it selects the closest",

"infill percentage. Does Cura have an algorithm to calculate a",

"of those possible values, or does it have a few",

"pattern for any of those possible values, or does it",

"for the infill percentage. Does Cura have an algorithm to",

"can set any whole number 0-100 for the infill percentage.",

"interface, I can set any whole number 0-100 for the",

"those possible values, or does it have a few patterns",

"Does Cura have an algorithm to calculate a pattern for"

] |

[

"it. So far I've printed test object and 2 others",

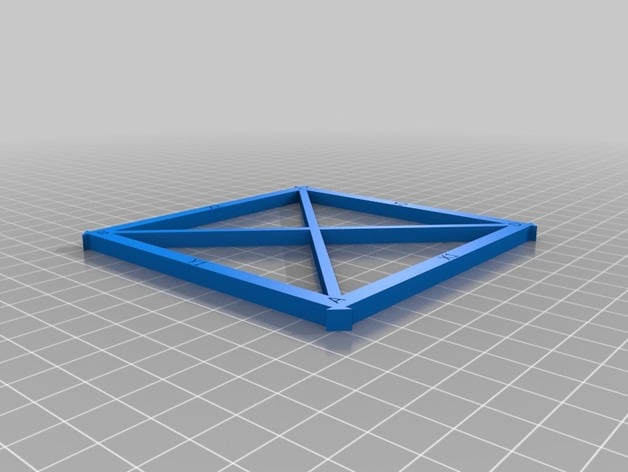

"to make image of 5 small one layer squares(one in",

"5 small one layer squares(one in each corner and one",

"I tried zbrush but found that it kind of complicated.",

"corner and one in center). Looking for recommendations of **simple**",

"So far I've printed test object and 2 others but",

"others but looks like there are problems with leveling. I",

"looks like there are problems with leveling. I want to",

"do it. I tried zbrush but found that it kind",

"there are problems with leveling. I want to make image",

"and one in center). Looking for recommendations of **simple** software/tutorials/approaches",

"to level it. So far I've printed test object and",

"software/tutorials/approaches to do it. I tried zbrush but found that",

"want to make image of 5 small one layer squares(one",

"I want to make image of 5 small one layer",

"Looking for recommendations of **simple** software/tutorials/approaches to do it. I",

"object and 2 others but looks like there are problems",

"one layer squares(one in each corner and one in center).",

"like there are problems with leveling. I want to make",

"layer squares(one in each corner and one in center). Looking",

"to do it. I tried zbrush but found that it",

"Mega** printer and trying to level it. So far I've",

"leveling. I want to make image of 5 small one",

"problems with leveling. I want to make image of 5",

"and 2 others but looks like there are problems with",

"with leveling. I want to make image of 5 small",

"each corner and one in center). Looking for recommendations of",

"image of 5 small one layer squares(one in each corner",

"squares(one in each corner and one in center). Looking for",

"in each corner and one in center). Looking for recommendations",

"2 others but looks like there are problems with leveling.",

"center). Looking for recommendations of **simple** software/tutorials/approaches to do it.",

"of **simple** software/tutorials/approaches to do it. I tried zbrush but",

"test object and 2 others but looks like there are",

"printed test object and 2 others but looks like there",

"**simple** software/tutorials/approaches to do it. I tried zbrush but found",

"printer and trying to level it. So far I've printed",

"small one layer squares(one in each corner and one in",

"trying to level it. So far I've printed test object",

"for recommendations of **simple** software/tutorials/approaches to do it. I tried",

"level it. So far I've printed test object and 2",

"it. I tried zbrush but found that it kind of",

"just bought **Anycubic i3 Mega** printer and trying to level",

"but looks like there are problems with leveling. I want",

"**Anycubic i3 Mega** printer and trying to level it. So",

"make image of 5 small one layer squares(one in each",

"i3 Mega** printer and trying to level it. So far",

"one in center). Looking for recommendations of **simple** software/tutorials/approaches to",

"are problems with leveling. I want to make image of",

"I've printed test object and 2 others but looks like",

"I've just bought **Anycubic i3 Mega** printer and trying to",

"in center). Looking for recommendations of **simple** software/tutorials/approaches to do",

"far I've printed test object and 2 others but looks",

"of 5 small one layer squares(one in each corner and",

"bought **Anycubic i3 Mega** printer and trying to level it.",

"recommendations of **simple** software/tutorials/approaches to do it. I tried zbrush",

"and trying to level it. So far I've printed test"

] |

[

"asking myself: > > What portable, measurable and roughly consistent",

"perimeters, infill, etc.) and tensile strength using > a specific",

"following goal: > > Determine the correlations between printing parameters",

"test specimen, and filament brand/model. > > > This goal",

"Determine the correlations between printing parameters (temperatures, > speeds, humidity,",

"experiment with the following goal: > > Determine the correlations",

"> a specific 3D printer, test specimen, and filament brand/model.",

"roughly consistent tensile strength test > does not require building",

"about a procedure that lies somewhere between this [hanging scale",

"outlined above or are there other specimens that > are",

"was thinking that, since the usual filaments have an ultimate",

"around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\" would be too much",

"> > I am thinking here about a procedure that",

"can be performed with > ready-made tools or machines available",

"a large hardware store, and > can be set up",

"somewhere between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely",

"there other specimens that > are more suitable? > >",

"> > What portable, measurable and roughly consistent tensile strength",

"machines available at a large hardware store, and > can",

"with > ready-made tools or machines available at a large",

"> > > This goal calls for two parts then:",

"> can be set up within 5 minutes? > >",

"that lies somewhere between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO",

"and ISO 527. Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388).",

"not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is",

"\"recoil\" would be too much and one needs to use",

"at a large hardware store, and > can be set",

"be set up within 5 minutes? > > > I",

"> does not require building a complicated machine, can be",

"test procedure, I've been asking myself: > > What portable,",

"are more suitable? > > > I was thinking that,",

"> > This goal calls for two parts then: a",

"and > can be set up within 5 minutes? >",

"minutes? > > > I am thinking here about a",

"procedure, I've been asking myself: > > What portable, measurable",

"would be too much and one needs to use a",

"procedure** and **test specimen**. For the test procedure, I've been",

"humidity, perimeters, infill, etc.) and tensile strength using > a",

"standardized **test procedure** and **test specimen**. For the test procedure,",

"I am thinking here about a procedure that lies somewhere",

"**test specimen**. For the test procedure, I've been asking myself:",

"scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116)",

"filaments have an ultimate strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps",

"tools or machines available at a large hardware store, and",

"procedure that lies somewhere between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and",

"ISO 3167 multipurpose test specimen an appropriate specimen for >",

"goal calls for two parts then: a standardized **test procedure**",

"an experiment with the following goal: > > Determine the",

"and filament brand/model. > > > This goal calls for",

"> > Determine the correlations between printing parameters (temperatures, >",

"for two parts then: a standardized **test procedure** and **test",

"parts then: a standardized **test procedure** and **test specimen**. For",

"require building a complicated machine, can be performed with >",

"procedure is defined, this begs the question: > > Is",

"Is the ISO 3167 multipurpose test specimen an appropriate specimen",

"the procedure is defined, this begs the question: > >",

"the question: > > Is the ISO 3167 multipurpose test",

"defined, this begs the question: > > Is the ISO",

"since the usual filaments have an ultimate strength of around",

"between printing parameters (temperatures, > speeds, humidity, perimeters, infill, etc.)",

"specific 3D printer, test specimen, and filament brand/model. > >",

"> I am thinking here about a procedure that lies",

"within 5 minutes? > > > I am thinking here",

"test > does not require building a complicated machine, can",

"> > Is the ISO 3167 multipurpose test specimen an",

"of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\" would be too",

"3D printer, test specimen, and filament brand/model. > > >",

"[40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\" would be too much and",

"a procedure that lies somewhere between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136)",

"specimen, and filament brand/model. > > > This goal calls",

"not require building a complicated machine, can be performed with",

"test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or",

"is defined, this begs the question: > > Is the",

"test specimen an appropriate specimen for > the test procedure",

"ISO 527. Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once",

"using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is defined,",

"527. Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the",

"available at a large hardware store, and > can be",

"> I was thinking that, since the usual filaments have",

"> are more suitable? > > > I was thinking",

"store, and > can be set up within 5 minutes?",

"> the test procedure outlined above or are there other",

"specimen an appropriate specimen for > the test procedure outlined",

"building a complicated machine, can be performed with > ready-made",

"or are there other specimens that > are more suitable?",

"the ISO 3167 multipurpose test specimen an appropriate specimen for",

"other specimens that > are more suitable? > > >",

"much and one needs to use a smaller, weaker specimen.",

"> Determine the correlations between printing parameters (temperatures, > speeds,",

"more suitable? > > > I was thinking that, since",

"that, since the usual filaments have an ultimate strength of",

"begs the question: > > Is the ISO 3167 multipurpose",

"hardware store, and > can be set up within 5",

"tensile strength test > does not require building a complicated",

"parameters (temperatures, > speeds, humidity, perimeters, infill, etc.) and tensile",

"> > I was thinking that, since the usual filaments",

"I've been asking myself: > > What portable, measurable and",

"myself: > > What portable, measurable and roughly consistent tensile",

"am thinking here about a procedure that lies somewhere between",

"Definitely not using [bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure",

"> > > I was thinking that, since the usual",

"> Is the ISO 3167 multipurpose test specimen an appropriate",

"appropriate specimen for > the test procedure outlined above or",

"Once the procedure is defined, this begs the question: >",

"I want to tackle an experiment with the following goal:",

"perhaps the \"recoil\" would be too much and one needs",

"with the following goal: > > Determine the correlations between",

"speeds, humidity, perimeters, infill, etc.) and tensile strength using >",

"tensile strength using > a specific 3D printer, test specimen,",

"filament brand/model. > > > This goal calls for two",

"can be set up within 5 minutes? > > >",

"are there other specimens that > are more suitable? >",

"the usual filaments have an ultimate strength of around [40-60",

"usual filaments have an ultimate strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/),",

"suitable? > > > I was thinking that, since the",

"This goal calls for two parts then: a standardized **test",

"strength using > a specific 3D printer, test specimen, and",

"brand/model. > > > This goal calls for two parts",

"two parts then: a standardized **test procedure** and **test specimen**.",

"printer, test specimen, and filament brand/model. > > > This",

"and roughly consistent tensile strength test > does not require",

"consistent tensile strength test > does not require building a",

"ready-made tools or machines available at a large hardware store,",

"thinking here about a procedure that lies somewhere between this",

"be too much and one needs to use a smaller,",

"(temperatures, > speeds, humidity, perimeters, infill, etc.) and tensile strength",

"I was thinking that, since the usual filaments have an",

"a complicated machine, can be performed with > ready-made tools",

"does not require building a complicated machine, can be performed",

"correlations between printing parameters (temperatures, > speeds, humidity, perimeters, infill,",

"a specific 3D printer, test specimen, and filament brand/model. >",

"set up within 5 minutes? > > > I am",

"the correlations between printing parameters (temperatures, > speeds, humidity, perimeters,",

"lies somewhere between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527.",

"this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely not using",

"What portable, measurable and roughly consistent tensile strength test >",

"tackle an experiment with the following goal: > > Determine",

"the test procedure outlined above or are there other specimens",

"ultimate strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\" would",

"the \"recoil\" would be too much and one needs to",

"strength test > does not require building a complicated machine,",

"an appropriate specimen for > the test procedure outlined above",

"hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is defined, this begs",

"to tackle an experiment with the following goal: > >",

"and **test specimen**. For the test procedure, I've been asking",

"multipurpose test specimen an appropriate specimen for > the test",

"have an ultimate strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the",

"above or are there other specimens that > are more",

"complicated machine, can be performed with > ready-made tools or",

"> > > I am thinking here about a procedure",

"test procedure outlined above or are there other specimens that",

"up within 5 minutes? > > > I am thinking",

"this begs the question: > > Is the ISO 3167",

"procedure outlined above or are there other specimens that >",

"too much and one needs to use a smaller, weaker",

"[pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is defined, this begs the question:",

"performed with > ready-made tools or machines available at a",

"measurable and roughly consistent tensile strength test > does not",

"infill, etc.) and tensile strength using > a specific 3D",

"specimen**. For the test procedure, I've been asking myself: >",

"or machines available at a large hardware store, and >",

"here about a procedure that lies somewhere between this [hanging",

"for > the test procedure outlined above or are there",

"using > a specific 3D printer, test specimen, and filament",

"> speeds, humidity, perimeters, infill, etc.) and tensile strength using",

"goal: > > Determine the correlations between printing parameters (temperatures,",

"> What portable, measurable and roughly consistent tensile strength test",

"etc.) and tensile strength using > a specific 3D printer,",

"> ready-made tools or machines available at a large hardware",

"an ultimate strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\"",

"printing parameters (temperatures, > speeds, humidity, perimeters, infill, etc.) and",

"3167 multipurpose test specimen an appropriate specimen for > the",

"strength of around [40-60 MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\" would be",

"want to tackle an experiment with the following goal: >",

"[hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely not using [bare",

"between this [hanging scale test](https://youtu.be/CZX8eHC7fws?t=136) and ISO 527. Definitely not",

"MPa](https://www.simplify3d.com/support/materials-guide/properties-table/), perhaps the \"recoil\" would be too much and one",

"and tensile strength using > a specific 3D printer, test",

"then: a standardized **test procedure** and **test specimen**. For the",

"specimen for > the test procedure outlined above or are",

"portable, measurable and roughly consistent tensile strength test > does",

"thinking that, since the usual filaments have an ultimate strength",

"question: > > Is the ISO 3167 multipurpose test specimen",

"For the test procedure, I've been asking myself: > >",

"be performed with > ready-made tools or machines available at",

"a standardized **test procedure** and **test specimen**. For the test",

"**test procedure** and **test specimen**. For the test procedure, I've",

"[bare hands](https://youtu.be/R7gpW6aCz0o?t=116) or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is defined, this",

"been asking myself: > > What portable, measurable and roughly",

"specimens that > are more suitable? > > > I",

"calls for two parts then: a standardized **test procedure** and",

"5 minutes? > > > I am thinking here about",

"large hardware store, and > can be set up within",

"that > are more suitable? > > > I was",

"machine, can be performed with > ready-made tools or machines",

"or [pliers](https://youtu.be/bmgSojocJ3c?t=388). Once the procedure is defined, this begs the",

"> This goal calls for two parts then: a standardized",

"the following goal: > > Determine the correlations between printing",

"the test procedure, I've been asking myself: > > What"

] |

[

"through it. Allowing you to reduce the retraction length and",

"amount of plastic being extruded. Is there any reasons that",

"Is there any reasons that this would not work or",

"of plastic being extruded. Is there any reasons that this",

"I came across this suggestion on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>.",

"suggestion on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce",

"any reasons that this would not work or actually decrease",

"work or actually decrease the performance of the bowden tube?",

"<https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce the stretching in the bowden",

"the plastic filament to run through it. Allowing you to",

"over the amount of plastic being extruded. Is there any",

"in the bowden tube you can add fiberglass packaging tape",

"the stretching in the bowden tube you can add fiberglass",

"along the tube. This would decrease the elasticity while still",

"this suggestion on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to",

"to reduce the stretching in the bowden tube you can",

"you to reduce the retraction length and have better control",

"better control over the amount of plastic being extruded. Is",

"came across this suggestion on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In",

"the tube. This would decrease the elasticity while still allowing",

"tube. This would decrease the elasticity while still allowing the",

"you can add fiberglass packaging tape lengthwise along the tube.",

"tape lengthwise along the tube. This would decrease the elasticity",

"lengthwise along the tube. This would decrease the elasticity while",

"This would decrease the elasticity while still allowing the plastic",

"to reduce the retraction length and have better control over",

"retraction length and have better control over the amount of",

"across this suggestion on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order",

"have better control over the amount of plastic being extruded.",

"this would not work or actually decrease the performance of",

"plastic being extruded. Is there any reasons that this would",

"order to reduce the stretching in the bowden tube you",

"reduce the stretching in the bowden tube you can add",

"fiberglass packaging tape lengthwise along the tube. This would decrease",

"the elasticity while still allowing the plastic filament to run",

"would not work or actually decrease the performance of the",

"being extruded. Is there any reasons that this would not",

"klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce the stretching in",

"it. Allowing you to reduce the retraction length and have",

"the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce the stretching",

"the retraction length and have better control over the amount",

"tube you can add fiberglass packaging tape lengthwise along the",

"Allowing you to reduce the retraction length and have better",

"there any reasons that this would not work or actually",

"and have better control over the amount of plastic being",

"github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce the stretching in the",

"add fiberglass packaging tape lengthwise along the tube. This would",

"while still allowing the plastic filament to run through it.",

"allowing the plastic filament to run through it. Allowing you",

"elasticity while still allowing the plastic filament to run through",

"that this would not work or actually decrease the performance",

"reasons that this would not work or actually decrease the",

"plastic filament to run through it. Allowing you to reduce",

"can add fiberglass packaging tape lengthwise along the tube. This",

"not work or actually decrease the performance of the bowden",

"decrease the elasticity while still allowing the plastic filament to",

"reduce the retraction length and have better control over the",

"stretching in the bowden tube you can add fiberglass packaging",

"filament to run through it. Allowing you to reduce the",

"run through it. Allowing you to reduce the retraction length",

"control over the amount of plastic being extruded. Is there",

"still allowing the plastic filament to run through it. Allowing",

"the amount of plastic being extruded. Is there any reasons",

"to run through it. Allowing you to reduce the retraction",

"extruded. Is there any reasons that this would not work",

"bowden tube you can add fiberglass packaging tape lengthwise along",

"on the klipper github, <https://www.facebook.com/groups/Hypercube.Evo/permalink/192106034761003/>. In order to reduce the",

"length and have better control over the amount of plastic",

"the bowden tube you can add fiberglass packaging tape lengthwise",

"would decrease the elasticity while still allowing the plastic filament",

"In order to reduce the stretching in the bowden tube",

"packaging tape lengthwise along the tube. This would decrease the"

] |

[

"so it's not a voltage drop. It's something in the",

"The thermistor works; it reads a little over 100kΩ in",

"temperature reading\") Boo. It stops working. I am sure my",

"here. I have a Tronxy x5s with a stock board",

"in my hot garage and the temperature changes after I",

"reading\")](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\") Boo. It stops working. I am",

"datasheet for the Arduino Mega 1248P and looked for other",

"7), solder the trace to the new pin, and change",

"reads for a few seconds, and then gives a negative",

"the extruder thermistor shorted so badly that the Analog to",

"and isolation](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace",

"explain how I arrived here. I have a Tronxy x5s",

"know I should probably just spring for a new board.",

"\"Photo of trace and isolation\") Then I changed the pin",

"messy but sound; I have used my voltmeter to verify",

"* I know that this is the same reading of",

"and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\") Then I changed",

"the old pin off from the thermistor port and soldered",

"to reflect the new pin. [](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet",

"But this temperature change only registers, as explained in the",

"// Analog Input (pin 33 extruder) #define TEMP_BED_PIN 6 //",

"over 100kΩ in my hot garage and the temperature changes",

"Tronxy X5s is a Sanguino): ``` // Temperature Sensors //",

"that ADC Pin0 was unused on the board, so I",

"port, it gives this same negative reading. * It is",

"same negative reading. * It is not attached to the",

"for other ADC pins I could use. I found that",

"as if it's been unplugged. * I know that this",

"the same reading of an unplugged thermistor because when you",

"thermistor port get 4.97 volts, so it's not a voltage",

"isolation\") Then I changed the pin used for that extruder",

"thermistor from a known-good port, it gives this same negative",

"though I know I should probably just spring for a",

"pins I could use. I found that ADC Pin0 was",

"I moved it to. I cut the old pin off",

"reading](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\")](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\") Boo. It stops",

"the new pin, and change the firmware to reflect the",

"reading in the `Pins_SANGUINOLOLU_11.h` config file (the old Melzi board",

"Sensors // #define TEMP_0_PIN 7 // Analog Input (pin 33",

"pinout\") [](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature",

"either go \"off\" or become disused after a few seconds.",

"\"off\" or become disused after a few seconds. Greater context:",

"I put it in my hand for a few minutes.",

"for months, but one day the extruder thermistor shorted so",

"explain what my issue is before I explain how I",

"get 4.97 volts, so it's not a voltage drop. It's",

"Boo. It stops working. I am sure my connections are",

"what \"pin 33\" was or used to be so I",

"months, but one day the extruder thermistor shorted so badly",

"principle of the thing. * The extruder thermistor accurately reads",

"changed the pin used for that extruder thermistor reading in",

"registers, as explained in the rest, for a few seconds.",

"reading consistently stayed at 260 °C, even when unplugged. I",

"up with a repair solution rather than replacing the board",

"It is attached to a new pin that I moved",

"bed) ``` Changed to ``` // Temperature Sensors // #define",

"my hand for a few minutes. But this temperature change",

"I have plans to do that anyway), so I downloaded",

"found that ADC Pin0 was unused on the board, so",

"the firmware that I am missing that causes that pin",

"extruder) #define TEMP_BED_PIN 6 // Analog Input (pin 34 bed)",

"(the old Melzi board for the Tronxy X5s is a",

"The temperature reading consistently stayed at 260 °C, even when",

"repairing for the sake of repairing, even though I know",

"used to be so I just put xx in the",

"it's not a voltage drop. It's something in the Arduino.",

"my software was supposedly good, so I flashed the new",

"seconds. Greater context: The printer was working great for months,",

"old pin off from the thermistor port and soldered the",

"new pin. [](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [ Boo. It stops working. I",

"pin to either go \"off\" or become disused after a",

"know that this is the same reading of an unplugged",

"the `Pins_SANGUINOLOLU_11.h` config file (the old Melzi board for the",

"when unplugged. I wanted to come up with a repair",

"I explain how I arrived here. I have a Tronxy",

"shorted so badly that the Analog to Digital pin on",

"I could use. I found that ADC Pin0 was unused",

"this same negative reading. * It is not attached to",

"pin that I moved it to. I cut the old",

"is before I explain how I arrived here. I have",

"Then I changed the pin in the configuration file, and",

"Input (pin xx extruder) #define TEMP_BED_PIN 6 // Analog Input",

"soldered the new pin to the traces of the port.",

"Input (pin 33 extruder) #define TEMP_BED_PIN 6 // Analog Input",

"old Melzi board for the Tronxy X5s is a Sanguino):",

"Pin0 was unused on the board, so I thought I'd",

"I have a Tronxy x5s with a stock board that",

"sure my connections are solid: I've tested for connectivity and",

"changed the pin in the configuration file, and it works,",

"new port and the heat bed thermistor port get 4.97",

"changes after I put it in my hand for a",

"Both the new port and the heat bed thermistor port",

"firmware that I am missing that causes that pin to",

"the firmware to reflect the new pin. [ ``` Changed to ``` // Temperature Sensors",

"only registers, as explained in the rest, for a few",

"am missing that causes that pin to either go \"off\"",

"4.97 volts, so it's not a voltage drop. It's something",

"stops working. I am sure my connections are solid: I've",

"\"Good temperature reading\") Yay! But after a few seconds... [, solder the trace to",

"hand for a few minutes. But this temperature change only",

"change the firmware to reflect the new pin. [ #define TEMP_BED_PIN 6 // Analog Input (pin",

"if it's been unplugged. * I know that this is",

"of the port. Then I changed the pin in the",

"Analog to Digital pin on the Arduino powering the Melzi",

"could use. I found that ADC Pin0 was unused on",

"a few seconds. * I am sure there's a configuration",

"Melzi board for the Tronxy X5s is a Sanguino): ```",

"is attached to a new pin that I moved it",

"was unused on the board, so I thought I'd isolate",

"heat bed thermistor port get 4.97 volts, so it's not",

"rest, for a few seconds. * I am sure there's",

"Sensors // #define TEMP_0_PIN 0 // Analog Input (pin xx",

"port and soldered the new pin to the traces of",

"bed) ``` I didn't know what \"pin 33\" was or",

"been unplugged. * I know that this is the same",

"the thing. * The extruder thermistor accurately reads for a",

"have plans to do that anyway), so I downloaded the",

"negative reading as if it's been unplugged. * I know",

"unused on the board, so I thought I'd isolate old",

"board. It's the principle of the thing. * The extruder",

"it works, for a while. * The electronics are messy",

"I downloaded the datasheet for the Arduino Mega 1248P and",

"the configuration file, and it works, for a while. *",

"from the thermistor port and soldered the new pin to",

"and isolation\") Then I changed the pin used for that",

"minutes. But this temperature change only registers, as explained in",

"in the firmware that I am missing that causes that",

"TEMP_BED_PIN 6 // Analog Input (pin 34 bed) ``` Changed",

"didn't know what \"pin 33\" was or used to be",

"causes that pin to either go \"off\" or become disused",

"that I moved it to. I cut the old pin",

"be so I just put xx in the comment. Anyway,",

"to the new pin, and change the firmware to reflect",

"it's been unplugged. * I know that this is the",

"// #define TEMP_0_PIN 0 // Analog Input (pin xx extruder)",

"the datasheet for the Arduino Mega 1248P and looked for",

"pin in the configuration file, and it works, for a",

"33\" was or used to be so I just put",

"the principle of the thing. * The extruder thermistor accurately",

"config file (the old Melzi board for the Tronxy X5s",

"* The electronics are messy but sound; I have used",

"on the Arduino powering the Melzi board was permanently damaged.",

"repair solution rather than replacing the board (even though I",

"isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\") Then I changed the",

"port. Then I changed the pin in the configuration file,",

"known-good port, it gives this same negative reading. * It",

"stock board that I am repairing for the sake of",

"x5s with a stock board that I am repairing for",

"* It is not attached to the original pin. It",

"bed thermistor port get 4.97 volts, so it's not a",

"ADC pins I could use. I found that ADC Pin0",

"extruder thermistor reading in the `Pins_SANGUINOLOLU_11.h` config file (the old",

"(even though I have plans to do that anyway), so",

"think it's best that I explain what my issue is",

"and looked for other ADC pins I could use. I",

"voltage. * The thermistor works; it reads a little over",

"\"Bad temperature reading\") Boo. It stops working. I am sure",

"new firmware, plugged it in, and turned it on: [ Boo. It stops working.",

"a while. * The electronics are messy but sound; I",

"the new port and the heat bed thermistor port get",

"But after a few seconds... [](https://i.stack.imgur.com/gbrNb.jpg",

"I am repairing for the sake of repairing, even though",

"temperature change only registers, as explained in the rest, for",

"is the same reading of an unplugged thermistor because when",

"probably just spring for a new board. It's the principle",

"\"Good temperature reading\")](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\") Yay! But after a",

"become disused after a few seconds. Greater context: The printer",

"solder the trace to the new pin, and change the",

"Analog Input (pin 34 bed) ``` Changed to ``` //",

"Arduino Mega 1248P and looked for other ADC pins I",

"#define TEMP_0_PIN 0 // Analog Input (pin xx extruder) #define",

"voltage. Both the new port and the heat bed thermistor",

"I thought I'd isolate old pin (ADC Pin 7), solder",

"the Tronxy X5s is a Sanguino): ``` // Temperature Sensors",

"a configuration somewhere in the firmware that I am missing",

"voltmeter to verify connectivity and voltage. * The thermistor works;",

"xx in the comment. Anyway, my hardware was good, and",

"the original pin. It is attached to a new pin",

"go \"off\" or become disused after a few seconds. Greater",

"for a few minutes. But this temperature change only registers,",

"gives a negative reading as if it's been unplugged. *",

"the Analog to Digital pin on the Arduino powering the",

"(ADC Pin 7), solder the trace to the new pin,",

"than replacing the board (even though I have plans to",

"34 bed) ``` Changed to ``` // Temperature Sensors //",

"hardware was good, and my software was supposedly good, so",

"the extruder or bed thermistor from a known-good port, it",

"damaged. The temperature reading consistently stayed at 260 °C, even",

"the pin used for that extruder thermistor reading in the",

"that extruder thermistor reading in the `Pins_SANGUINOLOLU_11.h` config file (the",

"connections are solid: I've tested for connectivity and voltage. Both",

"traces of the port. Then I changed the pin in",

"temperature reading](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\")](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\") Boo. It",

"the trace to the new pin, and change the firmware",

"Analog Input (pin xx extruder) #define TEMP_BED_PIN 6 // Analog",

"other ADC pins I could use. I found that ADC",

"#define TEMP_0_PIN 7 // Analog Input (pin 33 extruder) #define",

"in the rest, for a few seconds. * I am",

"was or used to be so I just put xx",

"then gives a negative reading as if it's been unplugged.",

"to do that anyway), so I downloaded the datasheet for",

"the board (even though I have plans to do that",

"I wanted to come up with a repair solution rather",

"for a few seconds, and then gives a negative reading",

"I just put xx in the comment. Anyway, my hardware",

"powering the Melzi board was permanently damaged. The temperature reading",

"sake of repairing, even though I know I should probably",

"for a while. * The electronics are messy but sound;",

"was good, and my software was supposedly good, so I",

"plugged it in, and turned it on: [: ``` // Temperature Sensors // #define",

"pin. It is attached to a new pin that I",

"extruder or bed thermistor from a known-good port, it gives",

"a new pin that I moved it to. I cut",

"I am sure there's a configuration somewhere in the firmware",

"in, and turned it on: [ #define TEMP_BED_PIN 6 // Analog Input (pin 34",

"it gives this same negative reading. * It is not",

"a few seconds... [](https://i.stack.imgur.com/gbrNb.jpg \"Bad",

"arrived here. I have a Tronxy x5s with a stock",

"moved it to. I cut the old pin off from",

"explained in the rest, for a few seconds. * I",

"was supposedly good, so I flashed the new firmware, plugged",

"reading\") Boo. It stops working. I am sure my connections",

"and my software was supposedly good, so I flashed the",

"there's a configuration somewhere in the firmware that I am",

"The electronics are messy but sound; I have used my",

"the new pin. [](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\") Yay! But after",

"of an unplugged thermistor because when you unplug either the",

"thing. * The extruder thermistor accurately reads for a few",

"it in my hand for a few minutes. But this",

"was permanently damaged. The temperature reading consistently stayed at 260",

"seconds, and then gives a negative reading as if it's",

"that anyway), so I downloaded the datasheet for the Arduino",

"Melzi board was permanently damaged. The temperature reading consistently stayed",

"plans to do that anyway), so I downloaded the datasheet",

"used for that extruder thermistor reading in the `Pins_SANGUINOLOLU_11.h` config",

"of trace and isolation](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo",

"I found that ADC Pin0 was unused on the board,",

"because when you unplug either the extruder or bed thermistor",

"I didn't know what \"pin 33\" was or used to",

"sure there's a configuration somewhere in the firmware that I",

"have a Tronxy x5s with a stock board that I",

"isolation](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and",

"the temperature changes after I put it in my hand",

"TEMP_0_PIN 7 // Analog Input (pin 33 extruder) #define TEMP_BED_PIN",

"Arduino powering the Melzi board was permanently damaged. The temperature",

"comment. Anyway, my hardware was good, and my software was",

"spring for a new board. It's the principle of the",

"am sure my connections are solid: I've tested for connectivity",

"few minutes. But this temperature change only registers, as explained",

"you unplug either the extruder or bed thermistor from a",

"are solid: I've tested for connectivity and voltage. Both the",

"and voltage. * The thermistor works; it reads a little",

"It's the principle of the thing. * The extruder thermistor",

"configuration somewhere in the firmware that I am missing that",

"extruder thermistor accurately reads for a few seconds, and then",

"my issue is before I explain how I arrived here.",

"for the sake of repairing, even though I know I",

"that pin to either go \"off\" or become disused after",

"to Digital pin on the Arduino powering the Melzi board",

"on: [](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\")",

"was working great for months, but one day the extruder",

"stayed at 260 °C, even when unplugged. I wanted to",

"trace and isolation\") Then I changed the pin used for",

"and soldered the new pin to the traces of the",

"this temperature change only registers, as explained in the rest,",

"put it in my hand for a few minutes. But",

"pin. [](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\")",

"of trace and isolation\") Then I changed the pin used",

"new board. It's the principle of the thing. * The",

"that the Analog to Digital pin on the Arduino powering",

"bed thermistor from a known-good port, it gives this same",

"a few minutes. But this temperature change only registers, as",

"port and the heat bed thermistor port get 4.97 volts,",

"do that anyway), so I downloaded the datasheet for the",

"pin to the traces of the port. Then I changed",

"temperature reading](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\")](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\") Yay! But",

"configuration file, and it works, for a while. * The",

"Analog Input (pin 33 extruder) #define TEMP_BED_PIN 6 // Analog",

"it on: [](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature",

"good, so I flashed the new firmware, plugged it in,",

"works; it reads a little over 100kΩ in my hot",

"but one day the extruder thermistor shorted so badly that",

"// #define TEMP_0_PIN 7 // Analog Input (pin 33 extruder)",

"works, for a while. * The electronics are messy but",

"from a known-good port, it gives this same negative reading.",

"at 260 °C, even when unplugged. I wanted to come",

"wanted to come up with a repair solution rather than",

"am sure there's a configuration somewhere in the firmware that",

"sound; I have used my voltmeter to verify connectivity and",

"Sanguino): ``` // Temperature Sensors // #define TEMP_0_PIN 7 //",

"even when unplugged. I wanted to come up with a",

"pin off from the thermistor port and soldered the new",

"``` I didn't know what \"pin 33\" was or used",

"[](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\") Then I",

"my connections are solid: I've tested for connectivity and voltage.",

"that I am missing that causes that pin to either",

"a known-good port, it gives this same negative reading. *",

"unplugged thermistor because when you unplug either the extruder or",

"pinout](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\")](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [: ``` // Temperature",

"solid: I've tested for connectivity and voltage. Both the new",

"it to. I cut the old pin off from the",

"working great for months, but one day the extruder thermistor",

"I changed the pin in the configuration file, and it",

"\"pin 33\" was or used to be so I just",

"the thermistor port and soldered the new pin to the",

"a few seconds. Greater context: The printer was working great",

"so I flashed the new firmware, plugged it in, and",

"and the temperature changes after I put it in my",

"Greater context: The printer was working great for months, but",

"of trace and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\") Then",

"it reads a little over 100kΩ in my hot garage",

"I have used my voltmeter to verify connectivity and voltage.",

"thermistor works; it reads a little over 100kΩ in my",

"connectivity and voltage. * The thermistor works; it reads a",

"original pin. It is attached to a new pin that",

"while. * The electronics are messy but sound; I have",

"as explained in the rest, for a few seconds. *",

"Then I changed the pin used for that extruder thermistor",

"software was supposedly good, so I flashed the new firmware,",

"after a few seconds. Greater context: The printer was working",

"garage and the temperature changes after I put it in",

"Digital pin on the Arduino powering the Melzi board was",

"temperature changes after I put it in my hand for",

"missing that causes that pin to either go \"off\" or",

"best that I explain what my issue is before I",

"and turned it on: [](https://i.stack.imgur.com/xrAAq.jpg",

"// Temperature Sensors // #define TEMP_0_PIN 0 // Analog Input",

"6 // Analog Input (pin 34 bed) ``` I didn't",

"new pin to the traces of the port. Then I",

"or bed thermistor from a known-good port, it gives this",

"I am missing that causes that pin to either go",

"though I have plans to do that anyway), so I",

"in the configuration file, and it works, for a while.",

"day the extruder thermistor shorted so badly that the Analog",

"printer was working great for months, but one day the",

"* The thermistor works; it reads a little over 100kΩ",

"The extruder thermistor accurately reads for a few seconds, and",

"same reading of an unplugged thermistor because when you unplug",

"// Analog Input (pin xx extruder) #define TEMP_BED_PIN 6 //",

"a negative reading as if it's been unplugged. * I",

"board was permanently damaged. The temperature reading consistently stayed at",

"to come up with a repair solution rather than replacing",

"for a new board. It's the principle of the thing.",

"I know that this is the same reading of an",

"Temperature Sensors // #define TEMP_0_PIN 0 // Analog Input (pin",

"attached to the original pin. It is attached to a",

"looked for other ADC pins I could use. I found",

"I changed the pin used for that extruder thermistor reading",

"Tronxy x5s with a stock board that I am repairing",

"\"Datasheet pinout\")](https://i.stack.imgur.com/Nr4D2.jpg \"Datasheet pinout\") [ #define TEMP_BED_PIN 6",

"disused after a few seconds. Greater context: The printer was",

"The printer was working great for months, but one day",

"consistently stayed at 260 °C, even when unplugged. I wanted",

"#define TEMP_BED_PIN 6 // Analog Input (pin 34 bed) ```",

"it's best that I explain what my issue is before",

"I flashed the new firmware, plugged it in, and turned",

"TEMP_BED_PIN 6 // Analog Input (pin 34 bed) ``` I",

"and the heat bed thermistor port get 4.97 volts, so",

"port get 4.97 volts, so it's not a voltage drop.",

"to a new pin that I moved it to. I",

"is a Sanguino): ``` // Temperature Sensors // #define TEMP_0_PIN",

"change only registers, as explained in the rest, for a",

"I know I should probably just spring for a new",

"but sound; I have used my voltmeter to verify connectivity",

"``` // Temperature Sensors // #define TEMP_0_PIN 0 // Analog",

"the new firmware, plugged it in, and turned it on:",

"Anyway, my hardware was good, and my software was supposedly",

"the Arduino Mega 1248P and looked for other ADC pins",

"the comment. Anyway, my hardware was good, and my software",

"file (the old Melzi board for the Tronxy X5s is",

"somewhere in the firmware that I am missing that causes",

"old pin (ADC Pin 7), solder the trace to the",

"that I am repairing for the sake of repairing, even",

"it in, and turned it on: [, so I downloaded the datasheet for the Arduino Mega",

"when you unplug either the extruder or bed thermistor from",

"electronics are messy but sound; I have used my voltmeter",

"// Analog Input (pin 34 bed) ``` I didn't know",

"34 bed) ``` I didn't know what \"pin 33\" was",

"tested for connectivity and voltage. Both the new port and",

"with a repair solution rather than replacing the board (even",

"seconds... [](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\")",

"(pin xx extruder) #define TEMP_BED_PIN 6 // Analog Input (pin",

"a Tronxy x5s with a stock board that I am",

"cut the old pin off from the thermistor port and",

"not a voltage drop. It's something in the Arduino. Any",

"\"Photo of trace and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\")",

"unplugged. I wanted to come up with a repair solution",

"[](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\") Yay!",

"so I thought I'd isolate old pin (ADC Pin 7),",

"a Sanguino): ``` // Temperature Sensors // #define TEMP_0_PIN 7",

"have used my voltmeter to verify connectivity and voltage. *",

"to either go \"off\" or become disused after a few",

"gives this same negative reading. * It is not attached",

"flashed the new firmware, plugged it in, and turned it",

"used my voltmeter to verify connectivity and voltage. * The",

"the Melzi board was permanently damaged. The temperature reading consistently",

"// Analog Input (pin 34 bed) ``` Changed to ```",

"thermistor because when you unplug either the extruder or bed",

"downloaded the datasheet for the Arduino Mega 1248P and looked",

"to. I cut the old pin off from the thermistor",

"turned it on: [](https://i.stack.imgur.com/xrAAq.jpg \"Good",

"I should probably just spring for a new board. It's",

"this is the same reading of an unplugged thermistor because",

"solution rather than replacing the board (even though I have",

"reading as if it's been unplugged. * I know that",

"few seconds. Greater context: The printer was working great for",

"new pin, and change the firmware to reflect the new",

"7 // Analog Input (pin 33 extruder) #define TEMP_BED_PIN 6",

"am repairing for the sake of repairing, even though I",

"a voltage drop. It's something in the Arduino. Any ideas?",

"a repair solution rather than replacing the board (even though",

"\"Datasheet pinout\") [](https://i.stack.imgur.com/eUuyj.jpg",

"I've tested for connectivity and voltage. Both the new port",

"temperature reading\") Yay! But after a few seconds... [](https://i.stack.imgur.com/Nr4D2.jpg",

"repairing, even though I know I should probably just spring",

"not attached to the original pin. It is attached to",

"thermistor port and soldered the new pin to the traces",

"trace and isolation](https://i.stack.imgur.com/eUuyj.jpg \"Photo of trace and isolation\")](https://i.stack.imgur.com/eUuyj.jpg \"Photo of",

"that I explain what my issue is before I explain",

"a few seconds, and then gives a negative reading as",

"before I explain how I arrived here. I have a",

"and it works, for a while. * The electronics are",

"are messy but sound; I have used my voltmeter to",

"temperature reading\")](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\") Yay! But after a few",

"issue is before I explain how I arrived here. I",

"Pin 7), solder the trace to the new pin, and",

"(pin 34 bed) ``` I didn't know what \"pin 33\"",

"my hot garage and the temperature changes after I put",

"off from the thermistor port and soldered the new pin",

"thermistor reading in the `Pins_SANGUINOLOLU_11.h` config file (the old Melzi",

"in my hand for a few minutes. But this temperature",

"extruder thermistor shorted so badly that the Analog to Digital",

"put xx in the comment. Anyway, my hardware was good,",

"pin, and change the firmware to reflect the new pin.",

"and voltage. Both the new port and the heat bed",

"I explain what my issue is before I explain how",

"thermistor shorted so badly that the Analog to Digital pin",

"replacing the board (even though I have plans to do",

"to ``` // Temperature Sensors // #define TEMP_0_PIN 0 //",

"[](https://i.stack.imgur.com/gbrNb.jpg \"Bad temperature reading\") Boo.",

"little over 100kΩ in my hot garage and the temperature",

"even though I know I should probably just spring for",

"reading of an unplugged thermistor because when you unplug either",

"volts, so it's not a voltage drop. It's something in",

"seconds. * I am sure there's a configuration somewhere in",

"the Arduino powering the Melzi board was permanently damaged. The",

"board for the Tronxy X5s is a Sanguino): ``` //",

"reading\")](https://i.stack.imgur.com/xrAAq.jpg \"Good temperature reading\") Yay! But after a few seconds..."

] |

[

"you \"auto home\" the print head, the nozzle stops off",

"the front of the print bed by 5-10 mm. Is",

"way to adjust the Y stop switch without making modifications",

"for alignment, and I noticed that when you \"auto home\"",

"that when you \"auto home\" the print head, the nozzle",

"purging the nozzle without dumping on the bed? It doesn't",

"stop switch without making modifications to it. It also didn't",

"off the front of the print bed by 5-10 mm.",

"through and checking/adjusting everything for alignment, and I noticed that",

"to it. It also didn't look like there was any",

"there is any way to adjust the Y stop switch",

"modifications to it. It also didn't look like there was",

"Is it perhaps by design to allow purging the nozzle",

"look like there was any easy way to move the",

"without making modifications to it. It also didn't look like",

"is any way to adjust the Y stop switch without",

"by 5-10 mm. Is that normal? Is it perhaps by",

"the print bed by 5-10 mm. Is that normal? Is",

"I was going through and checking/adjusting everything for alignment, and",

"noticed that when you \"auto home\" the print head, the",

"the nozzle without dumping on the bed? It doesn't appear",

"home\" the print head, the nozzle stops off the front",

"didn't look like there was any easy way to move",

"Is that normal? Is it perhaps by design to allow",

"on the bed? It doesn't appear that there is any",

"the Y stop switch without making modifications to it. It",

"the print head, the nozzle stops off the front of",

"switch without making modifications to it. It also didn't look",

"that normal? Is it perhaps by design to allow purging",

"it. It also didn't look like there was any easy",

"like there was any easy way to move the bed",

"\"auto home\" the print head, the nozzle stops off the",

"dumping on the bed? It doesn't appear that there is",

"doesn't appear that there is any way to adjust the",

"to allow purging the nozzle without dumping on the bed?",

"Ender 3. I was going through and checking/adjusting everything for",

"checking/adjusting everything for alignment, and I noticed that when you",

"it perhaps by design to allow purging the nozzle without",

"also didn't look like there was any easy way to",

"front of the print bed by 5-10 mm. Is that",

"alignment, and I noticed that when you \"auto home\" the",

"everything for alignment, and I noticed that when you \"auto",

"print head, the nozzle stops off the front of the",

"when you \"auto home\" the print head, the nozzle stops",

"mm. Is that normal? Is it perhaps by design to",

"appear that there is any way to adjust the Y",

"perhaps by design to allow purging the nozzle without dumping",

"the nozzle stops off the front of the print bed",

"of the print bed by 5-10 mm. Is that normal?",

"just received my new Creality Ender 3. I was going",

"to adjust the Y stop switch without making modifications to",

"new Creality Ender 3. I was going through and checking/adjusting",

"design to allow purging the nozzle without dumping on the",

"bed by 5-10 mm. Is that normal? Is it perhaps",

"I noticed that when you \"auto home\" the print head,",

"Creality Ender 3. I was going through and checking/adjusting everything",

"was going through and checking/adjusting everything for alignment, and I",

"3. I was going through and checking/adjusting everything for alignment,",

"there was any easy way to move the bed either.",

"head, the nozzle stops off the front of the print",

"nozzle stops off the front of the print bed by",

"any way to adjust the Y stop switch without making",

"and I noticed that when you \"auto home\" the print",

"allow purging the nozzle without dumping on the bed? It",

"going through and checking/adjusting everything for alignment, and I noticed",

"by design to allow purging the nozzle without dumping on",

"and checking/adjusting everything for alignment, and I noticed that when",

"print bed by 5-10 mm. Is that normal? Is it",

"normal? Is it perhaps by design to allow purging the",

"my new Creality Ender 3. I was going through and",

"making modifications to it. It also didn't look like there",

"adjust the Y stop switch without making modifications to it.",

"It also didn't look like there was any easy way",

"without dumping on the bed? It doesn't appear that there",

"that there is any way to adjust the Y stop",

"I just received my new Creality Ender 3. I was",

"nozzle without dumping on the bed? It doesn't appear that",

"stops off the front of the print bed by 5-10",

"It doesn't appear that there is any way to adjust",

"the bed? It doesn't appear that there is any way",

"received my new Creality Ender 3. I was going through",

"5-10 mm. Is that normal? Is it perhaps by design",

"bed? It doesn't appear that there is any way to",

"Y stop switch without making modifications to it. It also"

] |

[

"**Am I allowed to do that?** Is this the same",

"the other hand is full of 3d models of commercial",

"and publishing it? Sketchfab on the other hand is full",

"the result. **Am I allowed to do that?** Is this",

"the same like scanning a book and publishing it? Sketchfab",

"allowed to do that?** Is this the same like scanning",

"bought a buddha statue and I would like to scan",

"do that?** Is this the same like scanning a book",

"a buddha statue and I would like to scan it",

"publishing it? Sketchfab on the other hand is full of",

"buddha statue and I would like to scan it using",

"would like to scan it using photogrammetry and publish the",

"scan it using photogrammetry and publish the result. **Am I",

"same like scanning a book and publishing it? Sketchfab on",

"Sketchfab on the other hand is full of 3d models",

"book and publishing it? Sketchfab on the other hand is",

"publish the result. **Am I allowed to do that?** Is",

"I bought a buddha statue and I would like to",

"to do that?** Is this the same like scanning a",

"on the other hand is full of 3d models of",

"result. **Am I allowed to do that?** Is this the",

"like scanning a book and publishing it? Sketchfab on the",

"like to scan it using photogrammetry and publish the result.",

"Is this the same like scanning a book and publishing",

"statue and I would like to scan it using photogrammetry",

"scanning a book and publishing it? Sketchfab on the other",

"and I would like to scan it using photogrammetry and",

"using photogrammetry and publish the result. **Am I allowed to",

"it using photogrammetry and publish the result. **Am I allowed",

"I allowed to do that?** Is this the same like",

"this the same like scanning a book and publishing it?",

"it? Sketchfab on the other hand is full of 3d",

"photogrammetry and publish the result. **Am I allowed to do",

"that?** Is this the same like scanning a book and",

"other hand is full of 3d models of commercial products.",

"to scan it using photogrammetry and publish the result. **Am",

"a book and publishing it? Sketchfab on the other hand",

"and publish the result. **Am I allowed to do that?**",

"I would like to scan it using photogrammetry and publish"

] |

[

"it does this? That would let me set reminders to",

"reminders to check a print just at certain critical times.",

"layer view feature that lets you watch a simulation of",

"a simulation of the extruder head as it lays down",

"down material at each layer. Is it possible to get",

"as it does this? That would let me set reminders",

"view feature that lets you watch a simulation of the",

"that lets you watch a simulation of the extruder head",

"Cura has a layer view feature that lets you watch",

"possible to get Cura to show a time stamp as",

"me set reminders to check a print just at certain",

"you watch a simulation of the extruder head as it",

"head as it lays down material at each layer. Is",

"material at each layer. Is it possible to get Cura",

"show a time stamp as it does this? That would",

"extruder head as it lays down material at each layer.",

"set reminders to check a print just at certain critical",

"it possible to get Cura to show a time stamp",

"get Cura to show a time stamp as it does",

"would let me set reminders to check a print just",

"lets you watch a simulation of the extruder head as",

"as it lays down material at each layer. Is it",

"That would let me set reminders to check a print",

"layer. Is it possible to get Cura to show a",

"the extruder head as it lays down material at each",

"has a layer view feature that lets you watch a",

"let me set reminders to check a print just at",

"it lays down material at each layer. Is it possible",

"to get Cura to show a time stamp as it",

"stamp as it does this? That would let me set",

"this? That would let me set reminders to check a",

"at each layer. Is it possible to get Cura to",

"each layer. Is it possible to get Cura to show",

"to show a time stamp as it does this? That",

"simulation of the extruder head as it lays down material",

"lays down material at each layer. Is it possible to",

"time stamp as it does this? That would let me",

"of the extruder head as it lays down material at",

"a time stamp as it does this? That would let",

"a layer view feature that lets you watch a simulation",

"does this? That would let me set reminders to check",

"watch a simulation of the extruder head as it lays",

"Cura to show a time stamp as it does this?",

"Is it possible to get Cura to show a time",

"feature that lets you watch a simulation of the extruder"

] |

[

"can't alter and destroy them by accident. But... How do",

"you install them?! --- This is about installing firmware *directly*",

"mictrocontroller is [How to install new firmware via a Microcontroller?](https://3dprinting.stackexchange.com/questions/6685)",

"How do you install them?! --- This is about installing",

"To use another mictrocontroller is [How to install new firmware",

"firmware *directly* and *without* another microcontroller. To use another mictrocontroller",

"are pretty good as backups as one can't alter and",

"destroy them by accident. But... How do you install them?!",

"offer its firmware on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These are",

"pretty good as backups as one can't alter and destroy",

"accident. But... How do you install them?! --- This is",

"--- This is about installing firmware *directly* and *without* another",

"microcontroller. To use another mictrocontroller is [How to install new",

"alter and destroy them by accident. But... How do you",

"as one can't alter and destroy them by accident. But...",

"them?! --- This is about installing firmware *directly* and *without*",

"Creality does offer its firmware on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files.",

"as .hex files. These are pretty good as backups as",

"This is about installing firmware *directly* and *without* another microcontroller.",

"*without* another microcontroller. To use another mictrocontroller is [How to",

"use another mictrocontroller is [How to install new firmware via",

"firmware on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These are pretty good",

"These are pretty good as backups as one can't alter",

"one can't alter and destroy them by accident. But... How",

"its firmware on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These are pretty",

"and destroy them by accident. But... How do you install",

"files. These are pretty good as backups as one can't",

"about installing firmware *directly* and *without* another microcontroller. To use",

"installing firmware *directly* and *without* another microcontroller. To use another",

"on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These are pretty good as",

"another mictrocontroller is [How to install new firmware via a",

"and *without* another microcontroller. To use another mictrocontroller is [How",

"backups as one can't alter and destroy them by accident.",

".hex files. These are pretty good as backups as one",

"install them?! --- This is about installing firmware *directly* and",

"as backups as one can't alter and destroy them by",

"good as backups as one can't alter and destroy them",

"[creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These are pretty good as backups",

"But... How do you install them?! --- This is about",

"does offer its firmware on [creality3d.cn](https://www.creality3d.cn/download/firmware_c0001) as .hex files. These",

"another microcontroller. To use another mictrocontroller is [How to install",

"is about installing firmware *directly* and *without* another microcontroller. To",

"them by accident. But... How do you install them?! ---",

"*directly* and *without* another microcontroller. To use another mictrocontroller is",

"do you install them?! --- This is about installing firmware",

"by accident. But... How do you install them?! --- This"

] |

[

"regardless? This is with a 0.4 mm nozzle on an",

"to a PLA which isn't sticking well, I'm wondering if",

"the overall print quality settings. Am I going to get",

"I'm wondering if the first layer is best determined by",

"wondering if the first layer is best determined by the",

"for a 0.2 mm print. After changing to a PLA",

"stick to a 0.12 mm first layer regardless? This is",

"printer/tolerance/material, rather than the overall print quality settings. Am I",

"first layer regardless? This is with a 0.4 mm nozzle",

"first layer according to the print quality, so a 0.12",

"layer is best determined by the printer/tolerance/material, rather than the",

"print quality settings. Am I going to get more predictable",

"layer for a 0.08 mm print, and 0.28 mm for",

"0.28 mm for a 0.2 mm print. After changing to",

"to scale my first layer according to the print quality,",

"layer according to the print quality, so a 0.12 mm",

"predictable results if I stick to a 0.12 mm first",

"which isn't sticking well, I'm wondering if the first layer",

"I going to get more predictable results if I stick",

"mm print. After changing to a PLA which isn't sticking",

"Up till now, I've tended to scale my first layer",

"the printer/tolerance/material, rather than the overall print quality settings. Am",

"rather than the overall print quality settings. Am I going",

"now, I've tended to scale my first layer according to",

"I've tended to scale my first layer according to the",

"according to the print quality, so a 0.12 mm first",

"0.2 mm print. After changing to a PLA which isn't",

"Am I going to get more predictable results if I",

"print, and 0.28 mm for a 0.2 mm print. After",

"a 0.2 mm print. After changing to a PLA which",

"print quality, so a 0.12 mm first layer for a",

"to a 0.12 mm first layer regardless? This is with",

"to the print quality, so a 0.12 mm first layer",

"the print quality, so a 0.12 mm first layer for",

"mm for a 0.2 mm print. After changing to a",

"layer regardless? This is with a 0.4 mm nozzle on",

"going to get more predictable results if I stick to",

"if I stick to a 0.12 mm first layer regardless?",

"more predictable results if I stick to a 0.12 mm",

"a 0.08 mm print, and 0.28 mm for a 0.2",

"than the overall print quality settings. Am I going to",

"mm first layer regardless? This is with a 0.4 mm",

"if the first layer is best determined by the printer/tolerance/material,",

"I stick to a 0.12 mm first layer regardless? This",

"scale my first layer according to the print quality, so",

"my first layer according to the print quality, so a",

"mm first layer for a 0.08 mm print, and 0.28",

"After changing to a PLA which isn't sticking well, I'm",

"quality settings. Am I going to get more predictable results",

"isn't sticking well, I'm wondering if the first layer is",

"and 0.28 mm for a 0.2 mm print. After changing",

"till now, I've tended to scale my first layer according",

"print. After changing to a PLA which isn't sticking well,",

"0.08 mm print, and 0.28 mm for a 0.2 mm",

"the first layer is best determined by the printer/tolerance/material, rather",

"changing to a PLA which isn't sticking well, I'm wondering",

"is best determined by the printer/tolerance/material, rather than the overall",

"a PLA which isn't sticking well, I'm wondering if the",

"first layer for a 0.08 mm print, and 0.28 mm",

"mm print, and 0.28 mm for a 0.2 mm print.",

"get more predictable results if I stick to a 0.12",

"a 0.12 mm first layer for a 0.08 mm print,",

"0.12 mm first layer regardless? This is with a 0.4",

"a 0.12 mm first layer regardless? This is with a",

"well, I'm wondering if the first layer is best determined",

"by the printer/tolerance/material, rather than the overall print quality settings.",

"determined by the printer/tolerance/material, rather than the overall print quality",

"This is with a 0.4 mm nozzle on an Anet-A8.",

"best determined by the printer/tolerance/material, rather than the overall print",

"settings. Am I going to get more predictable results if",

"to get more predictable results if I stick to a",

"PLA which isn't sticking well, I'm wondering if the first",

"so a 0.12 mm first layer for a 0.08 mm",

"first layer is best determined by the printer/tolerance/material, rather than",

"for a 0.08 mm print, and 0.28 mm for a",

"sticking well, I'm wondering if the first layer is best",

"results if I stick to a 0.12 mm first layer",

"quality, so a 0.12 mm first layer for a 0.08",

"overall print quality settings. Am I going to get more",

"tended to scale my first layer according to the print",

"0.12 mm first layer for a 0.08 mm print, and"

] |

[

"would love to start a small engraving business without having",

"hardware. Using scrap parts at home, or parts from broken",

"make a laser engraver at home? My cousin managed to",

"start a small engraving business without having to purchase expensive",

"love to start a small engraving business without having to",

"ways to make a laser engraver at home? My cousin",

"are there any ways to make a laser engraver at",

"parts from broken CD players, are there any ways to",

"Using scrap parts at home, or parts from broken CD",

"there any ways to make a laser engraver at home?",

"any ways to make a laser engraver at home? My",

"a laser engraver at home? My cousin managed to make",

"from broken CD players, are there any ways to make",

"engraving business without having to purchase expensive hardware. Using scrap",

"home, or parts from broken CD players, are there any",

"without having to purchase expensive hardware. Using scrap parts at",

"cousin managed to make one of his own from scraps.",

"at home, or parts from broken CD players, are there",

"at home? My cousin managed to make one of his",

"My cousin managed to make one of his own from",

"to make a laser engraver at home? My cousin managed",

"to purchase expensive hardware. Using scrap parts at home, or",

"laser engraver at home? My cousin managed to make one",

"or parts from broken CD players, are there any ways",

"players, are there any ways to make a laser engraver",

"small engraving business without having to purchase expensive hardware. Using",

"broken CD players, are there any ways to make a",

"a small engraving business without having to purchase expensive hardware.",

"to start a small engraving business without having to purchase",

"home? My cousin managed to make one of his own",

"expensive hardware. Using scrap parts at home, or parts from",

"CD players, are there any ways to make a laser",

"I would love to start a small engraving business without",

"having to purchase expensive hardware. Using scrap parts at home,",

"parts at home, or parts from broken CD players, are",

"purchase expensive hardware. Using scrap parts at home, or parts",

"scrap parts at home, or parts from broken CD players,",

"engraver at home? My cousin managed to make one of",

"business without having to purchase expensive hardware. Using scrap parts"

] |

[

"down again. [](https://i.stack.imgur.com/P5yjv.jpg) The bottom .25\" of the",

"on layer separation](https://i.stack.imgur.com/G5lab.jpg)](https://i.stack.imgur.com/G5lab.jpg) The only possible failure mode I can",

"pretty well. Prints looked great. However, I installed [a more",